Industrial Camera

Table of Contents

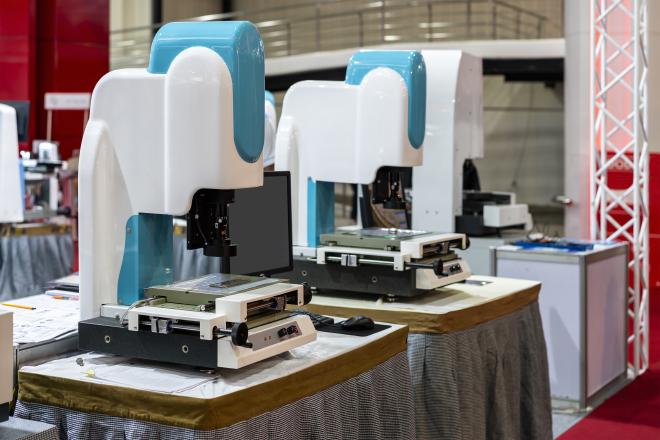

Industrial Camera for Product Inspection #

Overview #

This project involved designing an industrial camera system for product inspection, utilizing a dual-sensor setup for enhanced optical zoom capabilities. The system was built around a Xilinx FPGA and featured advanced image processing, enabling high-performance frame acquisition and manipulation.

Key Features and Achievements #

- Dual-Sensor Setup: Integrated two identical Sony sensors with different lenses to achieve optical zoom functionality.

- Advanced Image Processing Pipeline:

- Frame acquisition from the Sony sensor.

- Debayering, white balance adjustment, and vignette removal.

- Image zooming and cropping for customized output.

- High-Speed Sensor Interface:

- Operated at the maximum bus speed of the device’s speed grade.

- Implemented dynamic phase alignment (DPA) to ensure reliable communication.

- AXI-Based Architecture:

- Utilized an AXI bus for video data handling, ensuring compatibility and efficient integration of pre-existing Xilinx IPs.

- Memory Management: Processed images were stored in memory for efficient access by a Zynq processor.

- High-Speed Transmission: Images were further processed on Zynq and transmitted over Ethernet for real-time analysis.

Technical Details #

- Hardware: Xilinx FPGA, Sony sensors, Zynq processing unit.

- Development:

- Designed and implemented the FPGA architecture in VHDL.

- Verified using SystemVerilog testbenches.

- Integrated pre-existing Xilinx IP cores into the design.

- Technologies Used:

- Xilinx Vivado for synthesis and implementation.

- Verilog/SystemVerilog for verification.

- AXI bus for internal video data routing.

- Image Pipeline: Acquired and corrected images stored in memory before being accessed by Zynq for further processing.

Challenges and Solutions #

- High-Speed Communication: Overcame bus speed limitations by implementing dynamic phase alignment (DPA) to maintain reliable sensor communication at maximum speed.

- AXI Integration: Successfully adapted the design to incorporate pre-existing Xilinx IP cores, leveraging the AXI protocol for efficient video data handling.

- Synchronization: Managed synchronization between two sensors for seamless optical zoom integration.

- Processing Efficiency: Optimized FPGA resources to handle the entire image processing pipeline without bottlenecks.

Outcome #

The camera system delivered exceptional performance in industrial product inspection, leveraging dual-sensor optical zoom and real-time Ethernet transmission. Its robust image processing pipeline, AXI-based architecture, and high-speed communication met demanding industrial requirements.